Quality Control

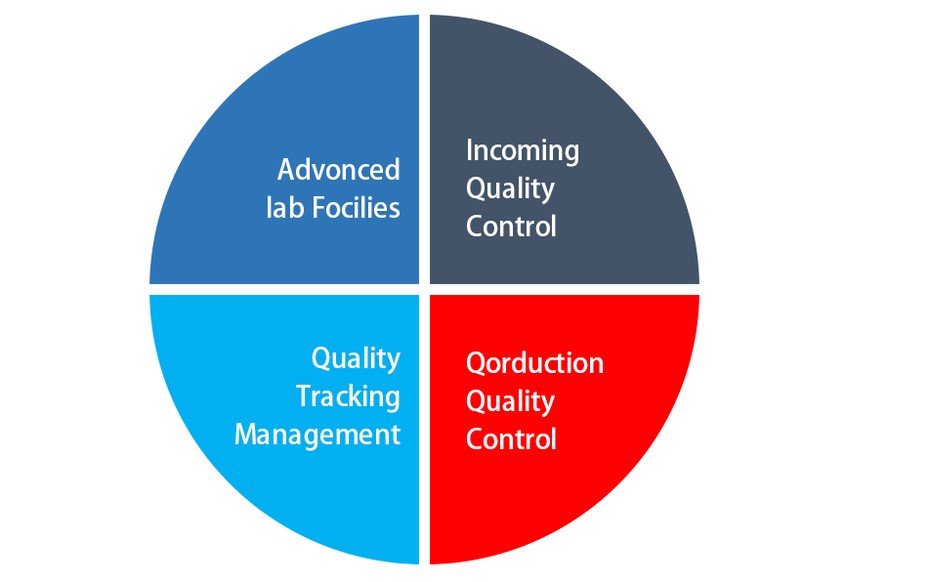

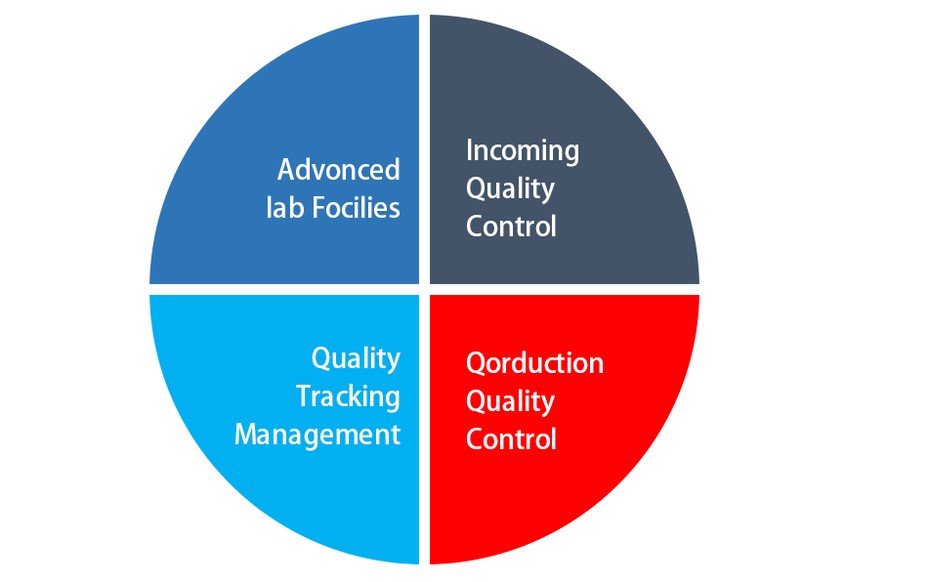

Dongguan Common Intelligent Technology Co., Ltd values product quality control especially in its hardware and software devices, which account for about 8% of the company's sales revenue.

To follow through on this commitment to quality, Dongguan Common Intelligent Technology Co., Ltd has built the world's leading energy-saving integrated performance laboratory for air-to-water heat pumps. The laboratory received approval from SGS can conduct third-party testing certification independently at the facility.

This laboratory can control testing environment conditions (for instance, DB: -30oC-53oC, relative humidity: 30%-95%); measure testing heat pumps’ refrigerating capacity, power consumption, electricity specifications and other technical data; sample and analyze different parts’ working temperature, electrical properties and electrical specifications. The equipment at the Dongguan Common Intelligent Technology Co., Ltd laboratory is controlled by either an automated controller or a human interface controller. In addition, the computer can sample, analyze and archive the test results, then output the testing report in English, and finally analyze the testing data.

Dongguan Common Intelligent Technology Co., Ltd integrated performance laboratory can meet product testing standard EN14511 and EN14825 of the European and American areas. What’s more, Dongguan Common Intelligent Technology Co., Ltd test types include UV, salt spray, RoHS, heat exchanger efficiency, constant temperature and humidity, pressure, temperature and other high level tests.

In the aspect of quality control, NEW ENERGY values communication and collaboration with the international quality certification bodies SGS.

Production Process

1.Intelligent Production Process

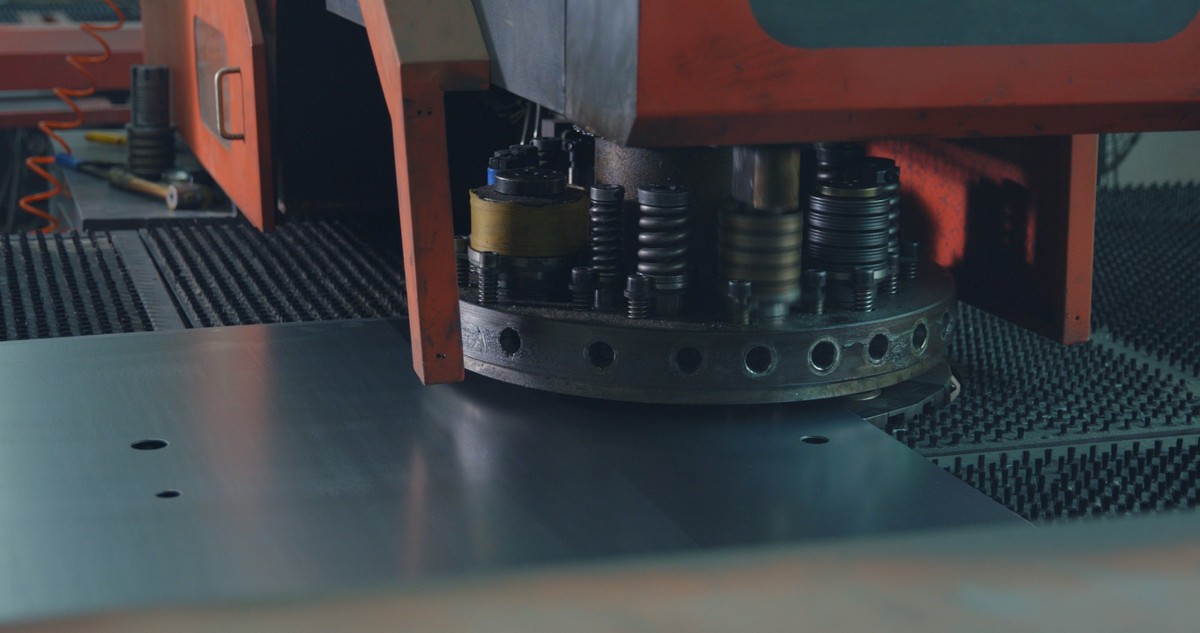

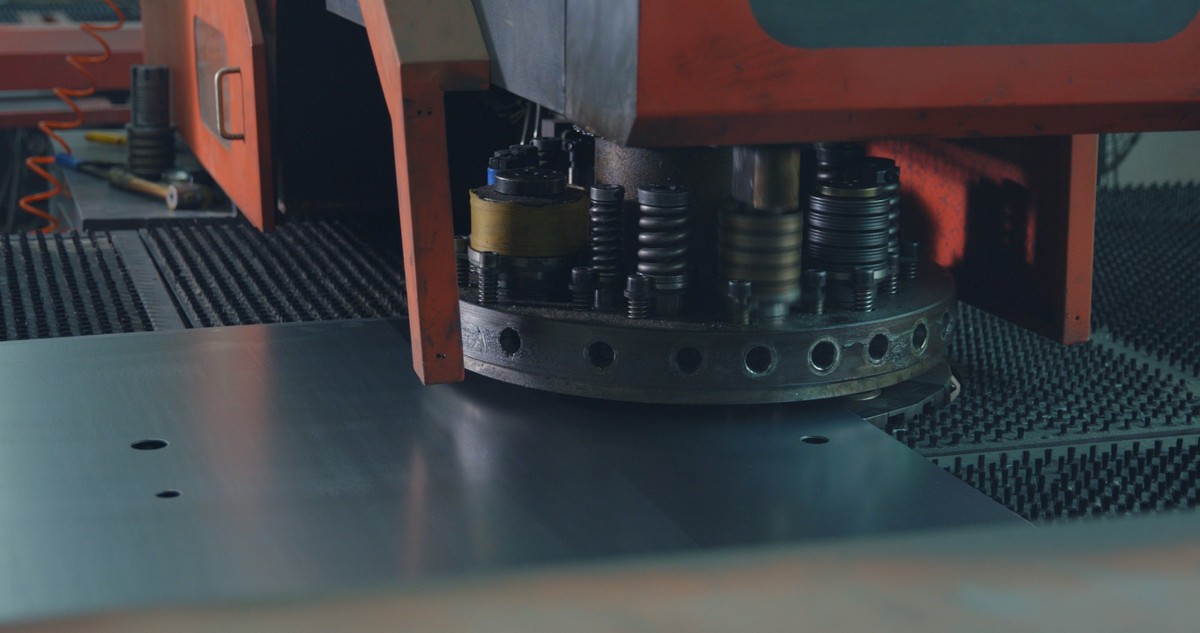

Forlssman products are independently developed and produced, using intelligent equipment to cut, punch and weld more efficiently and accurately. At the same time, professionals take turns to check online continuously to ensure that the quality and appearance of the products are optimized.

|

|

|

Automatic shell plate cutting

| Automatic shell plate CNC punching

| Intelligent robot welding |

2.Intelligent Enamel Coating Production

The intelligent robot is used to apply enamel coating powder and enter the special line of enamel and then burn it at a high temperature of 860 degrees. The whole process is operated online by professionals with high efficiency and accuracy. The enamel liner water tank has corrosion resistance.The service life can reach more than 10 years.

3.Automated Assembly Line Production

The assembly process of the automatic assembly line has achieved high speed. At the same time, different positions are assigned special personnel online assemble , and each process is strictly controlled to ensure product quality and aesthetics.

4.Intelligent Equiment Testing Lab

Forlssman has low temperature aboratories and multiple testing equipment that meet the national standards, providing guarantee for product performance quality. It also provides favorable innovation space for the research and development team. Therefore, Forlssman has obtained several patent certificates within 15 years and has cooperated with customers from different countries in OEM or ODM.Forlssman always takes quality as the first principle and is responsible for customers.

5.Efficient Automatic Packaging

Efficient automatic packaging equipment, faster and more accurate packaging, and multi-production

Dongguan Common Intelligent Technology Co., Ltd values product quality control especially in its hardware and software devices, which account for about 8% of the company's sales revenue.

Dongguan Common Intelligent Technology Co., Ltd values product quality control especially in its hardware and software devices, which account for about 8% of the company's sales revenue.